Magnefine®

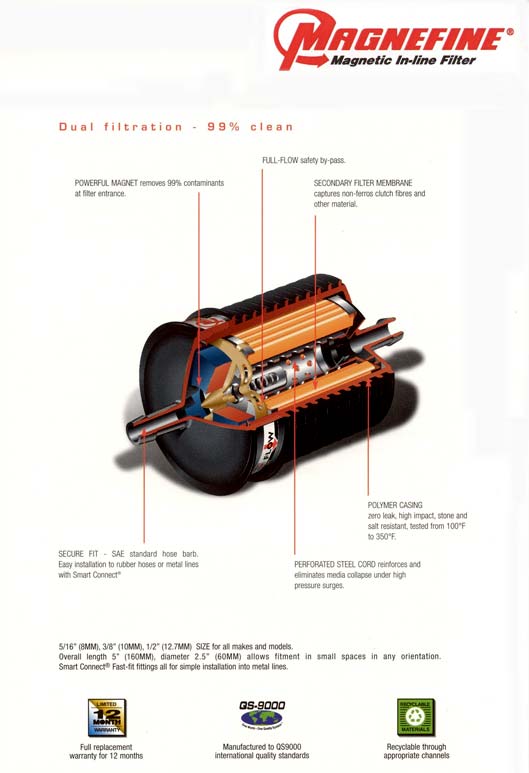

Simple and efficient, Magnefine® is a filtration appliance for cleaning and maintaining the hydraulic circuits of steering systems and automatic transmissions. The polymer casing, which has been tested to over 170°C, houses various components. Primary filtration begins in the 22/39 mm diameter ceramic magnetic bridge where the oil enters, keeping all parts magnetic regardless of their size.

The second filter consists in an oil resistant paper membrane and captures non-ferrous pollutants (residues of rubber, aluminium, copper and brass) that are over 25 Microns (on average, a human hair has a thickness of 70 Microns).

Lab tests indicate a total decontamination capacity of over 99%. The safety valves positioned at the core of the appliance guarantee the flow of oil, progressively increasing the opening in the event of blockage of the paper membrane. In total by-pass conditions, primary filtration is not interrupted as the oil manages in any case to cross the magnet releasing magnetic particles.

Magnefine®, whose production processes are compliant to QS-9000 standards, basically interrupts the “wear-and-tear chain”, thus extending the efficiency and duration of oil.